No.898 West Huanghe Road, Changzhou, Jiangsu, P.R.of China +86-182 06118609 [email protected]

Mining is a great use for the dozers which are some of the most crucial equipment you will need. Most people use only the top level but feel free to get creative and have fun!The dozer is a heavy type of bulldozer that assists in pushing dirt, rock and other materials during construction. This comes very handy as it helps the miners to access the minerals that are buried at depths underground. There are various kinds of dozer. Some of them are small and this is used for construction work, while there are some very big that have the ability to do mining work. In this text, we will learn how DINGSHENG TIANGONG dozers are used in mining, what makes them an essential tool in the mining industry, how they help miners capture more minerals in a shorter time period, and what expertise is required to operate them safely and effectively.

Dozing machines are important for cleaning up the areas around the rock, removing hurdles from the rocks, or moving dirt to create clean paths. They are absolutely essential because they keep the ground level and clear of debris. This allows miners some of the ease more of doing their job. Dozers are needed in many places since they are used in both underground mining and surface mining. In underground mining, for example, dozers can be used to clear soil and rock to allow the tunnels to be safe for miners. In surface mining, they can remove large tracts of surface area. They are also used in reclamation projects as well. This means that dozers can be used to restore the land to its pre-mined state, healthy and usable once mining is complete.

One major area of the mining industry is dozers. They make mining easier, faster and cheaper. Without dozers miners would have to move the materials and paths manually. Even then, it would take a long time and would also be dangerous. Alternatively, these tasks can easily be performed by dozers, allowing miners to concentrate on what they do best: extracting minerals.” In addition, these dozers minimize the damage to the environment. These are also important because they disturb less land in the mining process. This means areas can be left in better condition and is beneficial for nature and wildlife in the local area.

Dozers are of utmost importance when it comes to helping miners exceed their production goals. They are able to work around the clock, shifting enormous volumes of material with incredible speed and care. This is how the miners are able to extract more minerals in lesser time, thereby achieving higher production targets. Further, dozers can work in places that are difficult to access with other equipment. This function enables new mining opportunities to open up. In some challenging environments; such as steep hillsides or rocky areas; dozers can clear spaces for miners to drop off already extracted minerals. Dozer efficiency is essential to keeping mining operations running smoothly.

Dozer operates on large scale mining process. They can also work together with other machines like excavators to move vast amounts of materials in a very short time. This collaboration is particularly beneficial in open-pit mining, where significant areas must be excavated to recover minerals. Dozers can even operate in the worst environments. They are designed for extreme environments, such as those found in deserts, rainforests and mountains. Because of this ability, they are useful in many types of mining environments. This adaptability in terms of temperature also allows dozers to be usable across various types of mining projects, a major benefit for mining companies.

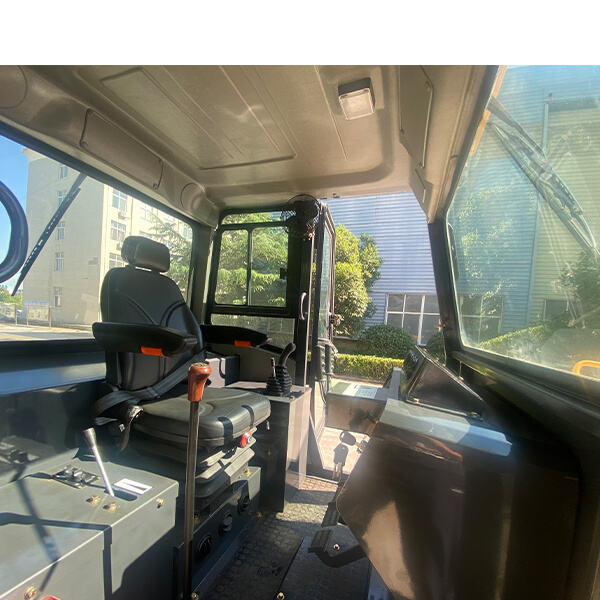

A crawler bulldozer is a specialized piece of equipment, requiring specialized skills to operate. Operators must be familiar with dozer operation and trained in the latest safety procedures. To ensure operator safety in harsh environments, DINGSHENG TIANGONG's dozers come with advanced safety technologies, including backup alarms and cameras. They also learn maintenance, in addition to driving the dozer. It used to be none of the recommended hydro dozer maintenance routines to ensure that the dozer runs smoothly and avoids the problem that occurs. That involves checking the oil, inspecting the tracks and making sure all other safety features are in working order.

as an international corporation which is part of the world we're committed to becoming a world-class manufacturer in the engineering equipment industry and related heavy industry we are proud to offer oem services for well-known international brands including wackerneuson terex jcb kato dozer for mining atlas sany and milacron we have created a broad trade pattern encompassing an array of goods and trade techniques our focus on construction machinery has led to a globalization of trade markets which has strengthened our position as a leader in the industry

Our affiliate factory, SINOMACH Changlin Co., Ltd. stands as a testimony to our engineering prowess and manufacturing quality. With over 60 years of dedicated RD and manufacturing experience, SINOMACH Changlin has consistently set new standards for excellence and innovation in the industry of construction machinery. The factory is regarded as an official National Technology Center, the facility is at forefront of technological advancements, driving the development of dozer for mining

SINOMACH-HI International dozer for mining Co Ltd prides itself on a robust global presence and exceptional service network Our international reach extends to 1 joint venture overseas factory that offers localized manufacturing capabilities as well as custom solutions to regional markets With three subsidiaries overseas we ensure seamless operations and a strategic approach to market growth Additionally our 5 overseas offices are vital interfaces for our clients with prompt and personalised service

We have dozer for mining sets of highly specialized equipment, which includes laser and flame cutting machines imported from other countries, beveling machinery brought from the world and large-scale CNC benders, as well as welding machines. This equipment lets us make 100,000 tonnes of steel per year.We also have over 120 processing centers in the United States and we are the first company to have a multi-purpose production line, sandblasting automatic line and an automatic coating line.